Industry-related monuments in the region of Końskie

***Historical Metallurgical Plant in Maleniec

Twenty-four kilometres west of Końskie, in Maleniec, on the Czarna River, there is an over two hundred year-old complex of rolling mills and nail plants. This historical stock of machinery, set in the natural countryside landscape, dates back to 1836.

Twenty-four kilometres west of Końskie, in Maleniec, on the Czarna River, there is an over two hundred year-old complex of rolling mills and nail plants. This historical stock of machinery, set in the natural countryside landscape, dates back to 1836.

At that time it included some rolling mills and 11 small and 4 big nailing machines for the production of nails cut from steel sheets. Due to the modernisation which took place at the end of the 19th century, the plant was equipped with other machines for procuction of spades and  shovels. The most interesting items, perfectly preserved up to the present, are: the production cycle of rolling steel sheets and manufacturing household tools, the houses of the rolling mill, the nail plant and the spade manufacture plant dating from 1839 as well as some unique machines. A special technological and tourist festival – Kuźnice Koneckie, where one can see all the historical machines and equipment running, is held there every July.

shovels. The most interesting items, perfectly preserved up to the present, are: the production cycle of rolling steel sheets and manufacturing household tools, the houses of the rolling mill, the nail plant and the spade manufacture plant dating from 1839 as well as some unique machines. A special technological and tourist festival – Kuźnice Koneckie, where one can see all the historical machines and equipment running, is held there every July.

The museum is open all year long. Opening hours: November-March, Mon – Fri 8:00-15:00 (closed at weekends) // April-October, Mon-Fri 8:00-15:00 (10:00-18:00 at weekends). The museum is closed on public holidays.

***Museum of the Old Polis h Industrial Region

h Industrial Region

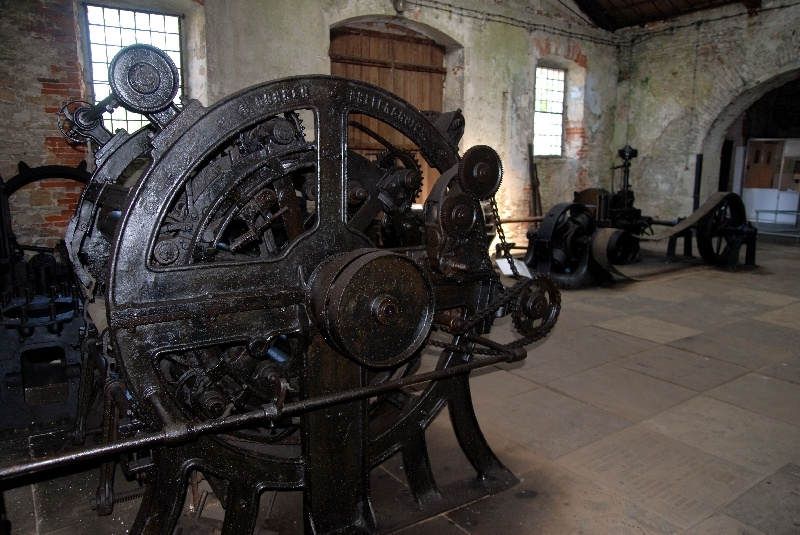

Sielpia is a great tourist attraction also because of the Museum of the Old Polish Industrial Region. It is one of the most valuable, in historical terms, industrial monuments in the country and Europe. It houses metalurgical exibits, mainly machines and tools, which had their glory days in XIX century. To one of its best items belongs a large iron water wheel with a diameter of 8,5 m designed by Philip de Girard, a steam engine from 1858 (the oldest one preserved in Poland) and a lathe from XIX century. The complex of rolling and puddling mills alongside the plant housing estate was built on the initiative of Stanisław Staszic and Ksawery Drucki-Lubecki. The first plan from 1821 assumed the construction of a hammer mill for 16 hammers. By 1830 there was the damming up of the Czerna Konecka river done, an 18-km long canal built that channeled the water for production purposes, an administrative building and a few outbuildings. In 1835 the plant construction was taken over the Polish Bank and by 1841 it erected the plant of rolling and puddling mills together with a housing estate of 29 buildings for the plant workers, probbaly according to the plans by Karol Knake.

On the plant square there is a production hall and two drying houses situated at the axis of the canal going west-east underground. At the internal plant yard between the drying houses there is an entrance to the canal. The estate plot is occupied by buildings, some of which are partly ruined: an adminstrative building, a residential one for the plant officers and a school.

There is also a hospital located near by. The mechanical equipment of the plant was probably manufactured in Starachowice, Rejów and Białogon and included, primarily, puddling furnaces, head hammers, rolling mill, metal cutting snips, bundler-stacker, reheating furnaces, 2 complexes of rod rolling mills, 2 wheels and a water turbine, the bbiggest pride of the contemporary museum.

The large iron water wheel with a diameter of 8,5 m designed by Philip de Girard powered by kinetic energy of falling water set in motion the plant machinery. It was a technical solution which was the first in Poland and one of the first in Europe used on such a broad scale. Iron ores for the plant in Sielpia were extracted in the neighbourhood of the Kawęczyn village (currently, the place of former extraction is called „the mine”). Extracted ores were melted down in large furnaces and the sourced iron was recast in a nearby rolling mill and puddling plant into steel. Per year, around 3000 tonnes of steelware was leaving the Sielpia plant. In the latter half of XIX the works deteriorated as a result of, inter alia, lack of resources, diminishing areas of forests where wood coal, necessary for the production, was burnt and due to the rising competition from the plants operating based on coal in the Dąbrowskie coal district.

The plant operated till 1921 and in 1934 it was transformed into a museum. In the period of WWII the place was devastated, the occupier looted it and took away 72 freight cars of its iron, machines and equipment. The works was restored in the years 1956-1959 and in 1962 the museum was officially reopened as athe Museum of the Old Polish Industrial Region (a subunit of the Museum of the Technology of the Polish Chief Technical Organisation in Warsaw). In the historical plant halls there are metallurgical exibits, mainly machines and tools, which had their glory days in XIX c.

To one of its most precious exibits, besides a large iron water wheel with a diameter of 8,5 m designed by Philip de Girard, belongs a steam blower from XIX c., a steam engine from 1858 (the oldest one preserved in Poland) and a lathe from XIX century. Visitors can also see a miniature model of the plant. Currently, the museum is closed for tourists due to its bad technical state and is planned to be revitalised in the near future.

Currently, the museum is closed for tourists due to its bad technical state and will be revitalised in the near future. The facility supervisor: Zarząd Obiektami Sportowymi i Rekreacyjnymi (Administration of Sports and Recreation Facilities) 26-200 Końskie, ul. kpt. Stoińskiego 3, tel. +48 41 372 41 01

***Blast Furnace Complex in Furmanów

The founder of the blast furnace complex on the Czarna river was Jan Małachowski, the then owner of the lands. The blast furnace remodelled in the 70s of XIX c., operated till 1907. It was at that time one of the biggest blast furnaces in the Old Polish Industrial Region.

The founder of the blast furnace complex on the Czarna river was Jan Małachowski, the then owner of the lands. The blast furnace remodelled in the 70s of XIX c., operated till 1907. It was at that time one of the biggest blast furnaces in the Old Polish Industrial Region.

Up to the present times survived the four brick, ground-floor factory buildings, unfortunately without the original equipment, a former fence, fragments of the damming and water channeling system and a four-storey verti cal shaft tower, serving in the past to pull out blast furnace charge called „gichta”. Unfortunately, the original equipment of the shaft tower did not survive either. At present the monument is owned by the sieve plant. Furmanów is located on the blue walking trail leading from Kuźniaki (in the Strawczyn Commune) to Skarżysko-Pogorzałe.

cal shaft tower, serving in the past to pull out blast furnace charge called „gichta”. Unfortunately, the original equipment of the shaft tower did not survive either. At present the monument is owned by the sieve plant. Furmanów is located on the blue walking trail leading from Kuźniaki (in the Strawczyn Commune) to Skarżysko-Pogorzałe.

***Water-powered smithy in Stara Kuźnica

The longest operating forge in the Końskie region with the equipment dating back to the 1st half of XIX c.

The longest operating forge in the Końskie region with the equipment dating back to the 1st half of XIX c.

In a small locality of Stara Kuźnica, situated on the Młynkowska river, there is one and only water-powered forge in Poland, presereved in its original shape from XIX c. Up to nowadays survived damming machines, watergates with a wooden trough channeling water to the wheel powering the machines. Inside there is a big pressure hammer, wooden box bellows called „Polish ones” as well as a lot of minor tools used in the production cycle such as sheet metal cutting snips, tongs or pliers. The smithy produced agricultural and household tools, (mainly ploughshares, axes, fittings, hooks or clamps) until 1957.The facility is currently closed for visitors.

powering the machines. Inside there is a big pressure hammer, wooden box bellows called „Polish ones” as well as a lot of minor tools used in the production cycle such as sheet metal cutting snips, tongs or pliers. The smithy produced agricultural and household tools, (mainly ploughshares, axes, fittings, hooks or clamps) until 1957.The facility is currently closed for visitors.

***Ruins of the Tilery and Paper Mill Complex in Machory

At the turn of XIX and XX c. ceramic works in Machory employed around 200 people and was at that time one of the best operating plants of the kind in the whole Russian partition area. The tiles manufactured in the Machory works were used to cover furnaces at the stations of the transiberian railway up to Władywostok.

At the turn of XIX and XX c. ceramic works in Machory employed around 200 people and was at that time one of the best operating plants of the kind in the whole Russian partition area. The tiles manufactured in the Machory works were used to cover furnaces at the stations of the transiberian railway up to Władywostok.

Machory is a locality with rich industrial traditions. In XVI c. there was a water-powered forge here, and in later years a blast furnace used to smelt iron. As indicated by the official data from the end of XVIII c. there were 4 facilities owned by Marcin dołęga, Lt Col of the Crown Army. The quantity of the pig iron produced here amounted to 3000 units of the centum weight (about 198 tonnes) per year, which was treated by three furnaces (in Polish „fryszerka”).

The third partition of Poland and the period of Napoleonic wars had a negative impact on the functioning of ironworks across Poland. In Machory, the production also fell substiantially to 806 units of the centum weight.

When the works was taken over by subsequent owners, its situation changed a lot. The Fraenkels – a known industrialists’ family from Warsaw, started in Machory in 1833 the first puddling plant in the (Congress) Kingdom of Poland.

The investment contributed to a large progress in the iron production at that time. An architect and builder of the plant in question was an outstanding metallurgist, born in the Kielce region, Wojciech Krygier. Pig iron was supplied by a local blast furnace, which operated till 1880. Machory developed very much under the governance of Ludwik Laski. In 1850 the production worth was tantamount to 12000 silver rubles, and in 1860 to 50000 ones.

At the turn of XIX and XX c. the manner of pig iron production was changed and persisted in using coke for heating blast furnaces. A little efficient production technology used in Machory was the main reason for the works collapse. The additional damages were made by the flood in 1923. As a result, the metalurgic production in Machory was put to a halt.

In the year 1898, on the land of the former smeltery, the then owner Ludwik Bayer opened a plant producing tiles and cardboard, being one of the most prominent plants in the Russion partition area. For tiles production they used white clay, extracted first in a mine existing in Machory from XIX c., and marl, brought from different corners of Poland.

Over XIX / XX c. the plant employed around 200 workers. It had its own sales depots in Warsaw, Łódź, Petersburg, Moscow and Odessa. In the initial production years ceramic furnace tiles form the Machory works amazed people with various ornaments. There were also decorations featuring genre or historical scenes manufactured. The Machory ware enjoyed popularity in the entire Russian Empire (they were used to cover furnaces at all the stations of the Transiberian Railway, up to Władywostok).

In the interwar period there was a generator installed in the plant, which provided electric energy for the works and the manorial buildings. It was powered by a water turbine by Francis which formerly propeller the rolling mills. The machines operated until 1970.

The remains of the Tilery and Paper Mill Complex include plant buildings (without the original equipment) and a well-preserved driving system along with a damming and water channeling one.The plant is in the state of ruin and unfortunately closed for visitors.

***Open-air vehicle exbition "Polish Roads" in Modliszewice

Around 300 exibits of cars, motorbikes, bikes and all made in Poland. They wait for fans of motorisation in Modliszewice, 3 km from Końskie, heading north-east in the direction of Łódź (National road no. 74). The Museum „Polish Roads” is a private collection of the vehicles of Polish motorization. On a large exibition one will see vehicles from the times of the Polish People’s Republic (in Polish abbreviated as „PRL”) and older ones from the interwar period. Besides popular „Fiats 125” and famous „Fiats 126p”, there are also lorries, buses and fire engines. The owners did their best to show unique vehicles on their exibition. The display can be seen Friday – Sunday at 9:00 – 17:00./ Group visits, outside opening hours, possible by prior arrangement / Admission fees: 25 PLN and 20 PLn. Children under 8 – free of charge./ Discounts for organised groupd (over 8 prs). / Phone: +48 604 256 303, e-mail: polskiedrogi@protonmail.com

Around 300 exibits of cars, motorbikes, bikes and all made in Poland. They wait for fans of motorisation in Modliszewice, 3 km from Końskie, heading north-east in the direction of Łódź (National road no. 74). The Museum „Polish Roads” is a private collection of the vehicles of Polish motorization. On a large exibition one will see vehicles from the times of the Polish People’s Republic (in Polish abbreviated as „PRL”) and older ones from the interwar period. Besides popular „Fiats 125” and famous „Fiats 126p”, there are also lorries, buses and fire engines. The owners did their best to show unique vehicles on their exibition. The display can be seen Friday – Sunday at 9:00 – 17:00./ Group visits, outside opening hours, possible by prior arrangement / Admission fees: 25 PLN and 20 PLn. Children under 8 – free of charge./ Discounts for organised groupd (over 8 prs). / Phone: +48 604 256 303, e-mail: polskiedrogi@protonmail.com

translated by Anna Kania, the employee of the Tourist Information Centre in Końskie